Benefits of Shell and Tube Oil Coolers

Performance and Durability for Rotary Screw Compressors

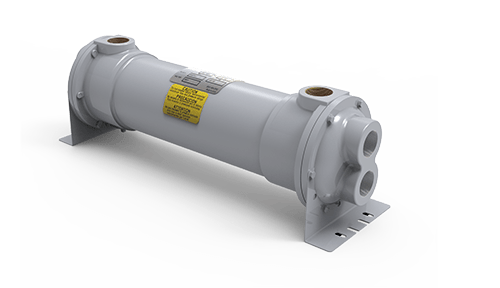

Shell and tube oil coolers are essential for rotary screw compressors, effectively cooling lubricating oil to maintain optimal operating temperatures. This reduces viscosity degradation, enhances lubrication, and minimizes wear on critical components. Using water from plant systems or closed-loop cooling towers, these coolers provide high thermal efficiency through their robust shell and tube design. While also applicable to piston/reciprocating compressors, they are primarily used in rotary screw systems due to their continuous operation and high oil flow requirements.

Equipment Protection

By maintaining proper oil temperatures, these coolers prevent overheating, reducing the risk of component failure and extending the lifespan of rotary screw compressors. Constructed from corrosion-resistant materials like stainless steel, they ensure durability and low maintenance in harsh industrial environments.

Applications

Shell and tube oil coolers are vital in industries such as manufacturing, automotive, and chemical processing, where rotary screw compressors drive high-demand operations. They ensure reliable performance in pneumatic systems, heavy machinery, and continuous-duty applications, maintaining oil quality and protecting critical processes under stringent industrial standards.

Air Cooled Aftercoolers

Air Cooled Applications

- High Cooling Efficiency

- Reliable Electric Motor

- Low Maintenance

Shell & Tube Oil Coolers

Water Cooled Applications

- High Thermal Efficiency

- Durable Construction

- Customizable Configurations