How to Select a Water Cooled Aftercooler

Selecting a watercooled aftercooler is fairly simply. You need to know the air flow rate, temperature and pressure. With these items you should be able to identify which cooler will work best for your application. If your not sure, or you have questions about this, call us: 1-888-226-8522, we'd be happy to help you.

Step 1

Determine if your compressor is a Two Stage or a Rotary Screw:

If you have a 2-Stage your compressor outlet temp is likely around 250F, and for Rotary Screw compressors figure about 200F. If you don't know, most newer comperessors are Rotary, whereas older ones tend to be 2-Stage (or Recip) style.

Alternatively, if you know your compressed air outlet temperature, (this is the hot compressed air you are looking to cool), this is ultimately what we're looking to know.

Step 2

Measure your pressure:

In order to size your compressed air aftercooler using these steps, your pressure should be 70 PSI or higher, for applicaitons with less than 70 PSI you will need to call for sizing, as pressure drop begins to present an issue; no worry here, it usually just means a slightly larger aftercooler to accomodate the lower pressure.

Step 3

Know your flow rate (SCFM):

Compressors are usually rated by SCFM / CFM, you need to know your maxumum flow rate in order to select the right size aftercooler.

Usually flow rate is known, if not, take compressor HP x 4.5 = SCFM

Step 4

Select the Aftercooler:

Using the information you gathered in step 1, 2 and 3, pick a column based on the type of compressor you are using and/or the inlet air temperature. Then work down the rows until you find the SCFM that is at or above the SCFM capacity of your compressor.

(Example: If you have a Rotary Screw compressor operating at 100PSI and 500 SCFM, you would look in the 2nd column under "Rotary Screw Compressor", and go down the rows until you see a number larger than 500, in this case you would settle on 655 SCFM, and then go all the way to the left to select the AB-1006.)

*Note: The performance of these aftercoolers are based on cooling compressed air to within 15F of the inlet water temperature. Water flow rate should be set at 2 GPM per 100 SCFM.

**SCFM Measured at 60F, 14.7 PSI, 50% RH

Quotes, Sales & Ordering Information: Water Cooled Aftercoolers, please contact us: 1-888-226-8522

Other Selection Considerations

Role of Aftercoolers

Aftercoolers are essential for cooling compressed air immediately after it leaves the compressor. This process reduces the air temperature, causing moisture to condense and allowing for its removal. Effective aftercoolers protect downstream equipment from corrosion, reduce the load on air dryers, and ensure the air is suitable for industrial applications.

Types of Aftercoolers

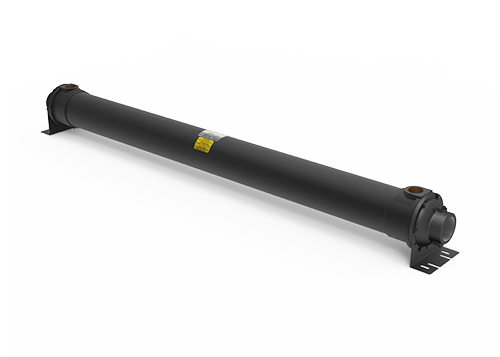

There are two primary types of aftercoolers: air-cooled and water-cooled. Air-cooled aftercoolers use ambient air to dissipate heat, making them ideal for environments with adequate ventilation. Water-cooled aftercoolers, on the other hand, use water as a cooling medium, offering superior efficiency in high-temperature or space-constrained settings. The choice depends on factors such as ambient conditions, available utilities, and operational requirements.

Moisture Separation

Aftercoolers work in tandem with moisture separators to remove condensed water from the compressed air stream. This step is critical to prevent water from entering downstream equipment, which could lead to corrosion, reduced efficiency, or product contamination. Properly designed aftercoolers ensure optimal moisture removal, enhancing system reliability.

Selection Considerations

Selecting the right aftercooler involves evaluating several factors, including compressor size, air flow rate, operating pressure, and ambient conditions. For example, a 100 HP compressor producing 400-500 CFM of air at 100 PSIG requires an aftercooler capable of handling these specifications while maintaining an approach temperature (the difference between the cooled air and the cooling medium) of 10-15°F for optimal performance. Additionally, consider the environment—dusty or corrosive settings may necessitate specific materials or designs.

Durability and Maintenance

Aftercoolers are built to withstand harsh industrial environments, with materials like stainless steel or copper resisting corrosion from moisture and chemicals. Regular maintenance, such as cleaning heat exchange surfaces and inspecting moisture separators, ensures long-term performance and efficiency. Industry-grade aftercoolers are designed for easy service, minimizing downtime and operational costs.